Services

Condition Monitoring solutions

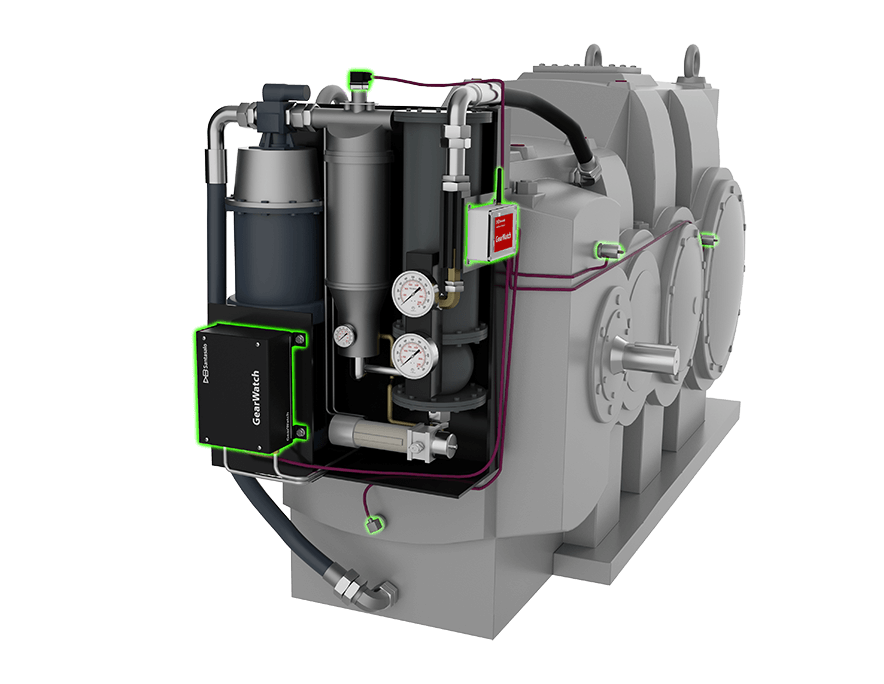

David Brown Santasalo's GearWatch condition management system is a smart, compact and value-adding tool for predictive remote process equipment monitoring.

WHY CHOOSE GEAR MONITORING?

GearWatch measures, records and analyses data, reporting any changes in measured parameters in real time, 24/7 via the internet.

Oil particle content monitoring enables early detection of potential gear unit failures months, or even a year in advance using oil and vibration monitoring techniques. This allows you to plan maintenance activities around your operational requirements and reduce downtime.

GearWatch can be tailored to your operating parameters and all data is monitored by gearbox experts at our control centre. Not only does it measure changes within the gearbox, it can also monitor a full range of equipment including motors, hydraulic systems and bearings, as required.

Our latest innovation, GearWatch Vibration Easy is a new way to implement condition monitoring of process-critical gears and other rotating machines in an automated, easy and inexpensive way.

KEY FEATURES

- Proactive approach to operation and maintenance

• Increases production and running time of drive train components by reducing risk of unplanned shutdown

• Operation and maintenance cost savings

• Longer lifetime for the gear units

• Optimised spare parts stock - Early detection of potential gear failures with simple and cost efficient measurements

• Oil particle content measurements make it possible to detect failures months or even a year before

• Corrective actions can be planned in advance

• Defects also detected on slow rotating component(s) - Analysis support by gearbox and drive train experts

• DBSantasalo condition monitoring engineers are certified to vibration analyst (ISO 18436.2) and lubricant analyst (ISO 18436.4) standards

• Clear recommendations and estimation of running time before service is required - Oil quality sensors

• Monitors oil condition online like oil ageing or mixing with other fluids

• Oil ageing monitoring helps to perform oil changes according to actual need, not periodically - Cost efficient and easy installations

• No need for factory specific server

• Ethernet or 2G/3G/4G connection to the secured and highly available cloud server

• Quick return on investment - Web based user-friendly application for analysis

• Access to data from everywhere where there is an internet connection

• Data replication to 3rd party cloud as an additional feature

THE BENEFITS

GearWatch can be tailored to your operating parameters and all data is monitored by gearbox experts at our control centre. Not only does it measure changes within the gearbox, it can also monitor a full range of equipment including motors, hydraulic systems and bearings, as required.

- Remote support from our Condition Monitoring Experts

- Clear recommendations and estimation of running time before service is required

- Access to your data 24/7

- Quick return on investment

- Condition monitoring engineers are ISO 18436.2 certified vibration analysts (Level II - IV)

- and ISO18426.4 certified Lubricant Analyst (Level I)

Monitoring packages

| Vibration Easy | Vibration | Standard | Oil Monitoring | Pro | |

| User Support | Yes | Yes | Yes | Yes | Yes |

| Oil Particle Count | Yes | Yes | Optional | ||

| Oil Quality | Yes | Optional | |||

| Vibration (wired) | Yes | Optional | |||

| Vibration (wireless) | Yes | Optional | |||

| Rotation Speed | Yes | Optional | Optional | Optional | |

| Temperature | Yes | Yes | Yes | Optional | |

| Oil Pressure | Optional | Optional | Optional | ||

| Load / Torque | Optional | ||||

| Oil Cleanliness Level | Optional | Optional | Optional | ||

| Oil Colour | Optional | ||||

| Oil Flow | Optional | ||||

| Force Detection Sensor | Optional | Optional | |||

| Analog Inputs to Import Signals | Optional |