DBS Transform from David Brown Santasalo

DBS Transform converts third-party gearboxes into high-performance DBS gearboxes through the utilisation of advanced 3D scanning technology to replace the rotating components. This service ensures minimal downtime during the reverse engineering process and can be executed at any location, effectively eliminating all potential obstacles for the customer.

Contact the team today:

· Service@dbsantasalo.com for DBS Transform enquiries.

Understanding our customer’s challenges

David Brown Santasalo has successfully assisted numerous customers in transforming their gearboxes to overcome a variety of challenges, which include the following:

Gearboxes are designed for extended lifespans in heavy-duty industrial environments, requiring high-quality systems to prevent unexpected shutdowns. However, during the lifespan of a gearbox, many factors can change, such as performance issues or the original manufacturer going out of business, leading end users to seek support from alternative providers.

Traditionally, while end users could engage with third-party service providers, they often remained dependent on the OEM (original equipment manufacturer) for spare parts and units. Conventional reverse engineering techniques were obstructive because customers couldn't take the gearbox offline long enough to reverse engineer it, leaving them reliant on the OEM due to intellectual property constraints.

Enter DBS Transform

Enter DBS Transform from David Brown Santasalo - an innovative solution born from the synergy of cutting-edge structured light 3D scanners along with almost three centuries of combined gearing expertise. These 3D scanners significantly reduce the time required to reverse engineer a gearbox. In many instances, the necessary data to design a new complete drivetrain can be captured within a scheduled shutdown window of a few hours!

Once the 3D scanning is completed, the gearbox can resume operation while a new drivetrain is designed and manufactured at one of our state-of-the-art manufacturing facilities. When the parts are ready, the transformation can be finalised at any of our global service centres, which span six continents, or even on the customer's own site. During this process, the gearcase undergoes a thorough inspection and refurbishment as required. The end result is a new gearbox with a recycled gearcase, ensuring peace of mind for the customer as the gearbox mounting interface remains identical to its original state!

DBS Transform delivers a significant advancement in gearbox maintenance and optimisation by enabling reverse engineering to be carried out without interrupting production. By allowing the gearbox to remain fully operational during the design and manufacturing phases, DBS Transform eliminates costly downtime and ensures continuous productivity. This approach not only safeguards output but also accelerates the path to improved performance—delivering value through reduced operational disruption and enhanced efficiency.

It's incredibly exciting to leverage cutting-edge technology alongside our world-leading gearbox expertise to tackle long-standing industry challenges. DBS has reverse-engineered gearboxes for decades, but now, with significantly reduced data capture times, we can transform any make and model of gearbox without causing unplanned downtime for our customers. The result of this is that the end user has the assurance of a new gearbox warranty and a comprehensive one-stop shop for all their aftermarket needs”

OEM FREEDOM

DBS Transform means end users are no longer bound to the original gearbox manufacturer, gaining the freedom to choose their aftermarket support and spare parts provider to meet their specific needs and requirements.

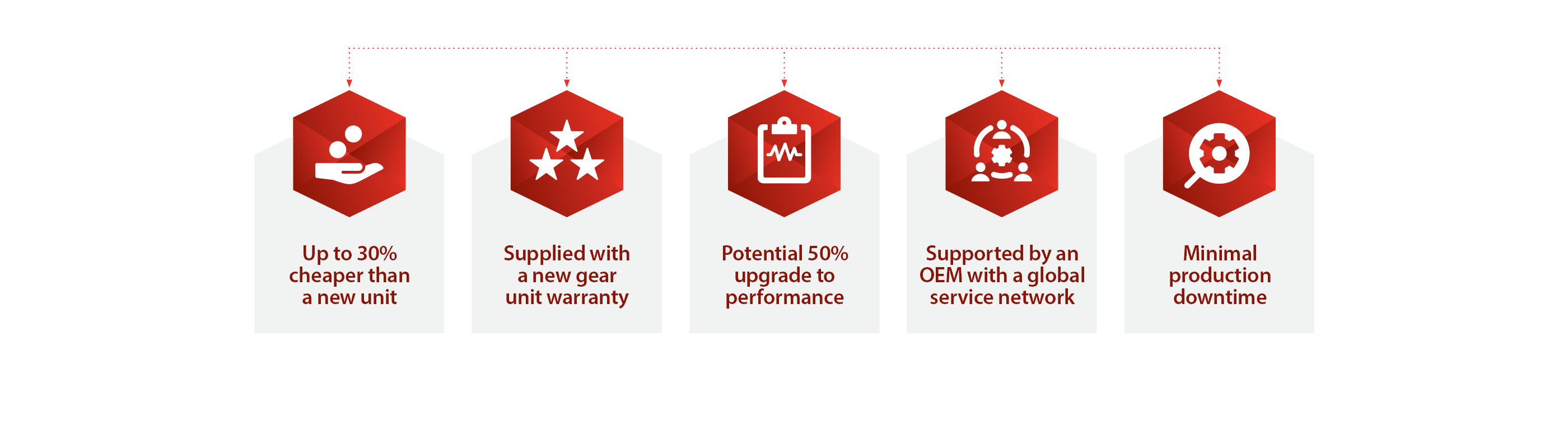

DBS Transform empowers end users to fully transition their gearbox aftermarket support to DBS, who offer proactive support throughout the entire lifecycle of the asset. Additionally, DBS Transform is more cost-effective than purchasing a new spare unit, offering quicker turnaround times, lower installation risks, and a new gearbox warranty!

Unlock the full potential of your gearbox with DBS Transform:

CONTACT US

Find out how we can Transform your operations:

· Service@dbsantasalo.com for DBS Transform enquiries.

Alternatively, find your local David Brown Santasalo location here: