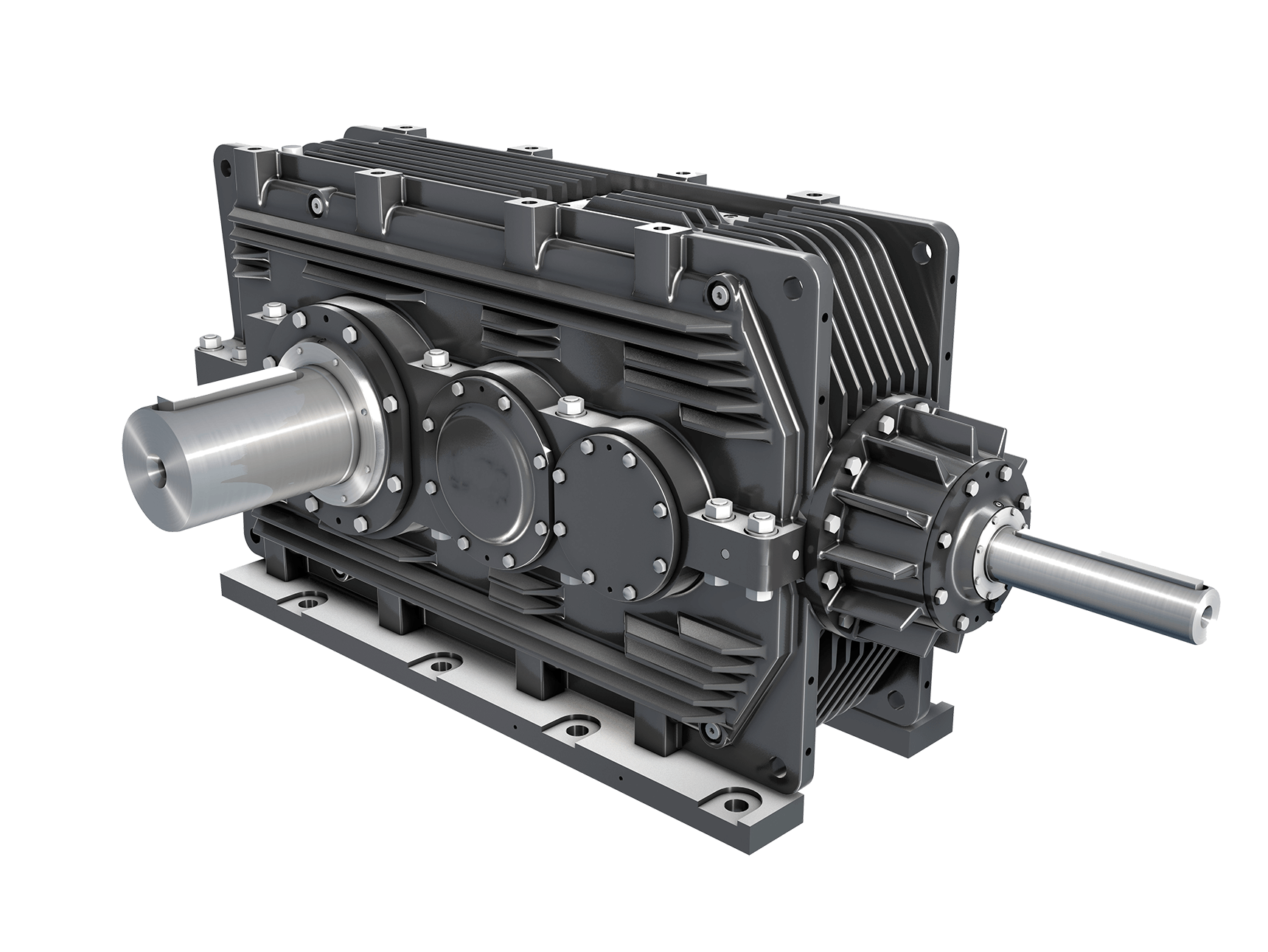

7 Reasons why our CX series is all torque, all action!

In today’s demanding and process critical industries, its vital to have a gearbox that not only provides high levels of performance and life expectancy, it exceeds it!

That’s where the CX series of conveyor gearboxes comes in, with a highly versatile range of configuration, sizes and features we can deliver our CX range as an individual unit or as part of a complete, optimised conveyor drive solution. We explore seven reasons our CX series is a market leading solution.

1. Class leading thermal capacity

Advancements in the capacity of gears to transmit higher loads have resulted in smaller gear units and smaller bearings, which are made possible through improvements in material quality & manufacturing accuracy. As a result, power can now be transmitted through much smaller units.

However, in order to control the heat, the gearbox must keep the oil below 90oC. It can be a limiting factor when selecting a unit if this heat control isn’t built in, particularly in high ambient countries.

The CX series from David Brown Santasalo provides an unrivalled solution. Our unique approach to the fan design delivers a small unit with excellent thermal ratings.

2. Flippable product design

In the modern production environment, the need to avoid downtime is a key factor. The amount of time that can be lost when replacing a unit in an emergency situation can be significant to a business, therefore reliability is key.

Imagine a tandem drive using two units driving a pulley, one at each side requiring one right hand unit and one left hand unit. The customer will need to ensure he has the spare units available for each hand, so that production doesn’t suffer should a failure occur.

Our CX Series has been designed by our team of experts. It enables you to purchase one standard unit, which can be quickly changed to the opposite handing in a few easy steps that requires no downtime. Delivering an exceptional solution to the somewhat costly approach of buying two spare units, or changing the handing through a strip & rebuild.

3. Increased bearing life

Bearings are the weakest part of any gear unit. They are more susceptible to damage by dirt, water, misalignment, vibration and operating loads. When they fail it is usually catastrophic and will typically result in damage to both the gears and casing.

David Brown Santasalo’s bearings are different, in conveyor applications a minimum L10 basic life span of over 60,000 hours or an L10a life span of 150,000hrs can be expected. That’s over six years and 15 years life expectancy respectively! This provides a capacity to withstand external factors, operating under tough conditions and extending operation for much longer periods of time.

Coupled with our state of the art GearWatch condition monitoring solution, we can ensure your gearbox continues to perform in a demanding environment.

4. Available in 19 sizes

The ideal unit should be sized to meet the exact design requirements, as anything more will give power capacity away. As each mechanical kW rating increases, the unit size needs to increase with it. That’s why David Brown Santasalo offer 19 different unit sizes within the CX range, to ensure our gearboxes meet the demands of any industrial application in process critical industries globally. Plus our range of CX gear systems are available in double reduction helical, or double and triple reduction bevel helical options.

5. CFD for optimisation

Computerised Fluid Dynamics (CFD) is a computerised model of the CX gear unit. This CFD enables us to model the passage of air across the outer surface of the case.

This is beneficial because it shows that if we can design the fins to control the air flow over the casing and balance the fan to give the optimum air speed, we can achieve a better thermal rating because the unit is being cooled more effectively.

6. FEA virtual loading

To optimise the power to weight ratio, we use Finite Element Analysis (FEA). A computer model of the case is created and broken down into a fine mesh of small elements. From here, we apply loads to the model, the computer then calculates the deflection of each element and the stress levels at the corners of each element.

From this data, we can determine where we can apply thinner wall thickness, meaning less weight and better thermal transfer within the case.

7. Simple lubrication system

Our CX range is a self-sufficient system, allowing the gearbox to operate at many speeds without the need for additional forced lubrication. To ensure it can withstand a wide range of temperatures, we rigorously test the CX series, which includes simulated cold starts. With a totally self-contained splash lubrication system inside the unit, the CX gearbox range keeps its cool in demanding conditions.

Find out more about the exciting CX Series gearbox range from David Brown Santasalo by contacting a member of your local team, here.